Material Intelligence, Decoded.

Multimodal AI agents that unlock material properties — helping enterprises grade quality, detect anomalies, trace provenance, and optimize processes end-to-end.

Industrial Science Meets Robust IT Stack

On-premise, secure AI agents

for compliance and governance

— delivering measurable results.

Deeply Embedded

Effortless integration with sensors, instruments, and Level 2/3 systems to capture valuable material insights.

Self Learning

AI-Agents

Context-aware agents never stop learning and deliver exceptional outcomes every day.

Agent: CoreSense

Ultrasound Profiling

Uses high-frequency waves to analyze internal structure, density, and voids without damaging the material.

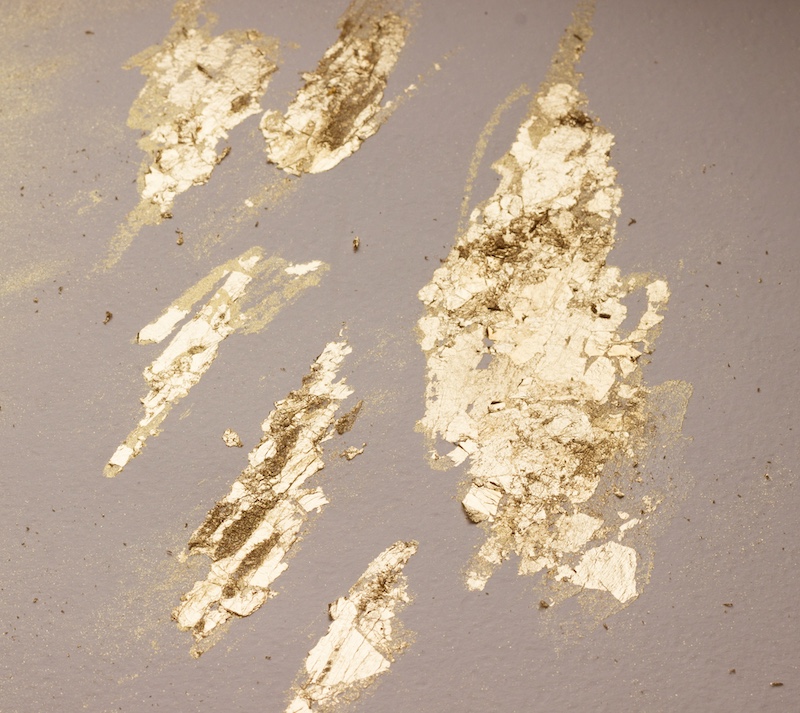

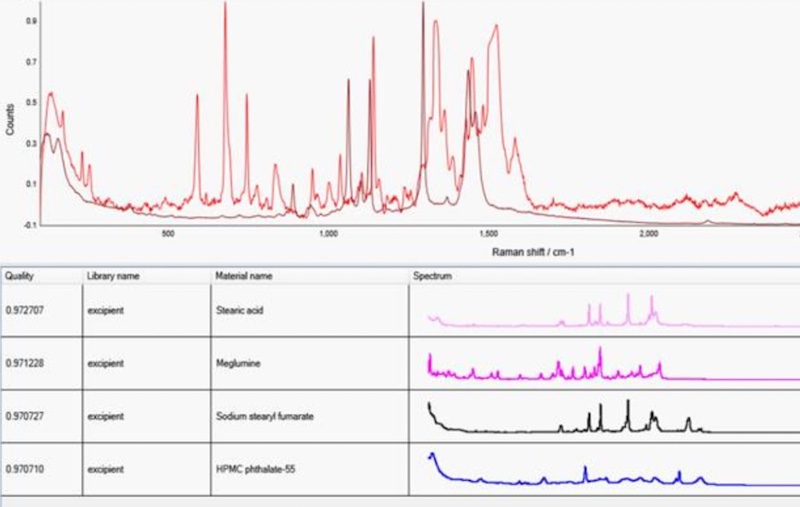

Spectroscopy Insights

Leverages absorption and emission spectra to determine material composition, purity, and chemical bonds.

SEM Surface Mapping

Captures high-resolution microstructural details, enabling detection of crystalline patterns, defects, and grain boundaries.

Chemical Composition Analysis

Integrates results from XRF, EDX, or titration tests to reveal precise elemental and compound-level composition.

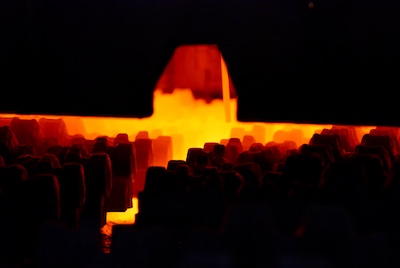

Thermal Property Detection

Uses thermal response patterns to understand heat capacity, conductivity, and phase transitions.

Microstructural Integrity

Analyzes grain orientation, porosity, and residual stress to assess material performance under extreme conditions.

Intrinsic Data

Material Chemistry

Extrinsic Data

Observable Insights

Agent: EdgeSense

Stress & Strain Mapping

Monitors material deformation under load, tension, and pressure using advanced sensor feedback.

Thermal Response Analysis

Tracks heat expansion, cooling curves, and thermal gradients to predict material stability.

Surface Anomaly Detection

Uses vision + laser profilometry to detect scratches, cracks, and micro-defects on material surfaces.

Vibration & Acoustic Monitoring

Captures resonance frequencies and acoustic signatures to spot structural weaknesses early.

Environmental Impact Assessment

Evaluates humidity, corrosion, UV exposure, and oxidation effects on material performance.

Fatigue & Wear Prediction

Predicts lifecycle degradation using real-time data from mechanical stress and operational cycles.

Agent: FlowSense

Provenance Tracking

Captures complete material genealogy, tracing it from raw source to finished product.

MES & Level 2/3 Integration

Hooks into manufacturing execution systems to align real-time process data with material intelligence.

Process Compliance Monitoring

Continuously checks SOP adherence, ensuring quality standards are met at every stage.

Instrument & Sensor Correlation

Aggregates data from lab tests, inline sensors, and machine feedback for contextual insights.

Material Routing Intelligence

Tracks where, when, and how each material moves across the supply chain and shop floor.

Continuous Contextual Learning

Builds a dynamic material knowledge graph, improving insights as it learns from historical and live data.

Meta Data

Quarry to Quality

Using spectral fingerprinting, SEM imaging, and chemical composition analysis, CoreSense detects foreign particles, residual solvents, and cross-contamination at trace levels. Pharma manufacturers thus maintain strict quality standards, reduce batch failures, and meet FDA and GMP guidelines

CoreSense : Pharma, BioTech, R&D.

Using computer vision, contextual AI agents and deep integration with level2/3 systems, Awareye enables manufacturers to map raw material to finished product conversion, ensuring accurate traceability, quality control, and process compliance.

FlowSense : Processing, Manufacturing, Recyclying.

Value-added service businesses detect surface and structural defects in their products using vision and thermal sensing. By identifying anomalies early, it enables faster quality decisions, reduces rework, and ensures consistent customer satisfaction.

EdgeSense : Processing, Packaging, Value Added Services.

Frequently Asked Questions

Unlike generic AI platforms, Awareye is purpose-built for material science and process intelligence. We combine:

- Multimodal sensing → thermal, vision, spectroscopy, ultrasound

- Context-aware AI agents → intrinsic, extrinsic, and metadata-driven insights

- Tight integration with Level 2/3 systems → for governance, traceability, and SOP compliance

This unique combination gives enterprises deeper visibility, higher accuracy, and measurable ROI.

Awareye serves a wide range of industries where material properties and process efficiency are critical, including:

- Metals & Mining → heat signatures, alloy composition, quench monitoring

- Composites & Aerospace → void detection, ultrasonic analysis

- Pharma & Chemicals → spectral analysis, purity verification

- Manufacturing & Logistics → defect mapping, provenance tracking

Our platform is modular and scalable, making it ideal for diverse industrial environments.

Call US

Call: +1 650 504 9547

Work Hours

08:00AM - 05:00PM PST

Email Us

support@awareye.ai